MoniUPS

Remote UPS monitoring system

MoniUPS is the innovative remote monitoring system, able to control all brands and all kinds of UPS systems; acquire the data, elaborate them on a cloud application, and make it readily accessible 24 hours a day, everywhere in the world, through a tablet or a PC. MoniUPS doesn’t need a control over local network environment, granting real-time interaction and communication, without being based on the premise of external network access to the UPS. The periodic report (available online and in real time), the telemetry, and a wide series of warnings and alarms about the UPS system will make your critical applications more flexible, reliable and secure. Being able to remotely control a UPS, means having a specialist take care of your UPS 24 hours a day.

Thanks to constant monitoring, it is possible to maximise UPS availability (operation) with targeted actions such as vital parameters inspection, data analysis, comparison with his-torical data as well as predictive diagnosis. It is also possible to minimize downtime costs due to power failures, thanks to immediate identification of any malfunction with measures to solve the problem right from initial servicing. Compared to the diagnostics carried out in the field, remote diagnosis prevents any damage and reacts immediately in the best way, right from the start.

For all customers who acquired a UPS to protect their critical loads, this innovative tool will constantly monitor and supervise the whole installation, providing a predictive diagnosis. Due to the remote monitoring system, the UPS can communicate a warning message to our AEG Power Solutions experts, who will in turn make a remote diagnosis on the UPS, reach the site installation, and restore the UPS, before a failure can occur. This immediate reaction, and the resolution of potential faults at the first intervention are vital for critical applications, where power interruption occurs due to a UPS fault (coming from any possible problem), may cause extensive damage. For this purpose, it is funda-mental that any UPS status is immediately sent to the remote application, and can automatically define the priority of intervention. Recent statistics about remote monitoring systems indicated that nearly 40% of all potential faults were solved over the phone, with an immediate intervention.

System Benefits:

- Maximization of electrical system availability through constant monitoring, especially in critical environments

- Optimization of resources

- Lower operating costs

- Proactive analysis of data and trends compared with the entire install-base, in order to suggest corrective actions, thus ensuring best performances

- Supplying AEG PS service engineers with relevant data to help with minor and major problem-solving, thereby reducing service response times

- Preventing downtime with predictive analysis thus extending equipment life

- Supply customers with comprehensive reports with details on operational performance as well as the status of the UPS

At a glance:

Any UPS model (AEG Power Solutions or other brand), equipped with an SNMP-Ethernet card, can easily communicate with the MoniUPS cloud application through a gateway deployed on the local network.MoniUPS gateway supports a wide variety of UPS and SNMP brands and only needs to be installed in the same local network where the UPS is installed. A single gateway can support up to 8 UPS and more than one gateway can be installed within the same network. To properly communicate with the cloud application the gateway needs to only send data over the internet without involving dedicated networking configurations such as port-forwarding or NAT rules; in this way the installation is very simple and doesn’t involve complex and expensive field activities.Data is collected from the SNMP by a polling cycle sampled at a frequency that depends on the number of UPS monitored (usually one second), consolidated on the gateway and sent over to the cloud application every 15 seconds.

In case of an internet con-nection failure, the gateway on-board memory can store up to 4 hours of data (from 8 UPS simultaneously). This data will be handed over to the cloud once the connection is restored. Events and alarms received asynchronously from the SNMPs are relayed directly to the cloud with FIFO logic. Critical events will trigger notifications with different levels of severity, to the AEG PS service expert, directly to the customer, or both.All data, measures, alarms and events are stored on the cloud application, and is accessable to AEG PS service engineers. Each customer is granted a dedicated login: you can monitor the UPS installed, providing full access to all information about the operating status of your systems. Every month a technical report is automatically generated, available on the cloud application and delivered via email to customers. If during the previous month an event with high severity has occurred, the report may also include a technical comment from AEG Power Solutions service experts.

Battery replacement:

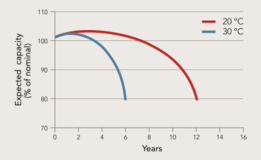

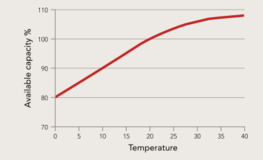

The battery is a vital part of the UPS system, which needs to be checked and controlled periodically. A fundamental parameter to be controlled during routine maintenance is the operating temperature, both for the batteries as well as for the battery room. A low temperature will have a negative impact upon batteries, decreasing the available capacity and also the dis-charge voltage (the viscosity increases, reducing the speed of the acid diffusion in the pores of the active material). Moreover, an increase of the battery operating temperature, will increase its capacity, due to variations in the viscosity and the resistance of the electrolyte (as shown in the 1st graph below). The nominal capacity of batteries are very sensitive with the operating temperature: at its normal operating temperature, batteries will have nominal capacity properties. After a long operating life with stable capacity values, the battery will decrease its properties and will be no longer reliable once it decreases at a value lower than 80% of its nominal value (end of life). For all the parameters shown above, our AEG PS experts recommend maintaing periodic controls on the battery room, reporting the exact temperature and suggesting any possible modification to the operating conditions. Apart from the operating conditions, other values are periodically monitored, such as:

- Battery voltage

- Recharging current

- Battery string voltage measurement

- Battery testing:

- Discharge test

- Battery current measurement (during the discharging period)

- Battery voltage verification before the test and at the end of the charge

- Minimum battery voltage

- Maximum discharging current.

Capacitors and fan replacement:

The most critical power components, according to their expected life are the capacitors, forming the DC filter downstream the rectifier, and the internally mounted cooling fans, which allow for correct air exchange to the internal electronic devices. Their expected life is strictly dependent on the hot air extracted. Regarding the capacitors, their expected life is strictly dependent upon the operating temperature (which then depends on the percentage of load applied to the UPS). Moreover, a good filtering action (DC ripple lower than 1%) will allow for lower battery temperatures, directly connected to the DC bus of the UPS, both in the recharging and in the discharging phase.

Security:

MoniUPS Gateway manages the highest level of security allowed by the SNMP version; implements and communi-cates with the cloud environ-ment through enterprise-grade standard HTTP over SSL/TLS layering (HTTPS), using X.509 certificates issued by recognized authorities and a public-key infrastructure; thus, helping to protect against man-in-the-middle attacks.

Additionally, it provides communication encryption of data exchanged between client and server, thereby ensuring against eavesdropping and tampering with and/or forging the contents of the communication. Gateway identification has a lightweight and efficient cryptographic system. All data exchange sessions are subject to authentication based on the exchange of a hashed string. As hash functions are expected to be non-invertible, it is then not possible to reconstruct the input data from its hash value alone without spending great amounts of computing time.

Communication between the Gateway and cloud is always unidirectional (Gateway to cloud); in this way it is not pos-sible by design, to access the Gateway on the local network from any remote location.The remote monitoring appli-cation runs on a state-of-the-art cloud environment on the Microsoft Azure infrastructure, where every service and VMs run under a private network exposing only web endpoints.High availability is provided by multiple geography de-ployment, cluster-managed web and external services, mirrored db instances and a dedicated monitoring system. The application front-end can be accessed via web browser through user authentication and an HTTPS connection.