HPI

UPS system

60 – 300 kVA

Input: 3-phase

Output: 3-phase

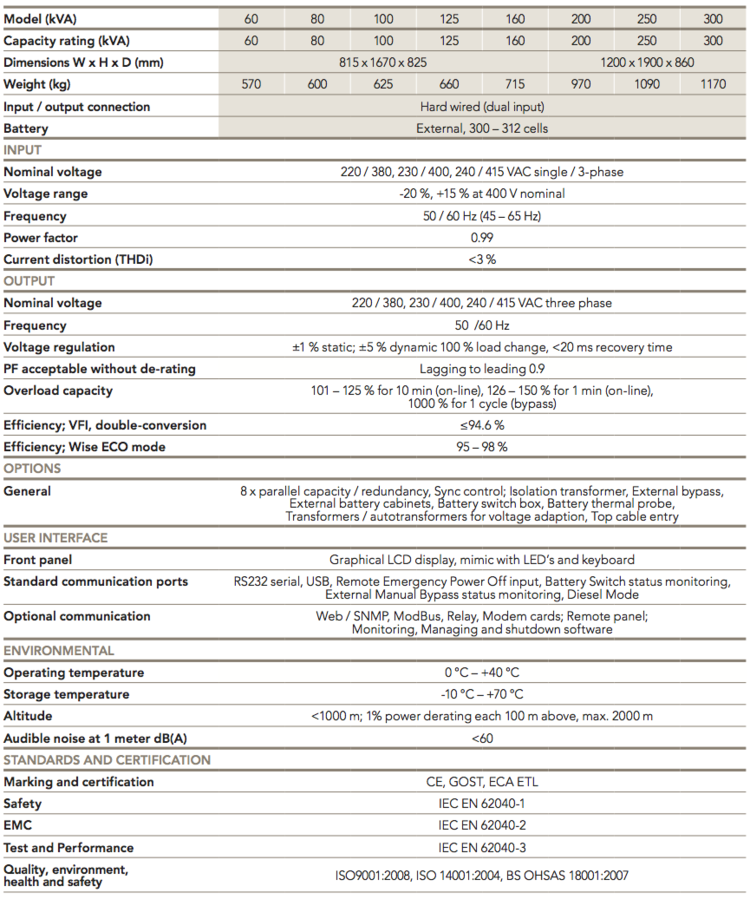

UPS system HPI combines management of THD and power factor, low cost of ownership and power protection in a highly reliable solution guaranteed by the most advanced technology. The HPI model UPS uses a completely new IGBT input rectifier design, encompassing an advanced PFC (Power Factor Control) which is capable of keeping input current THDi (Total Harmonic Distortion) at a level of less than 3 % and input power factor within 1 % of unity, even when only small loads are applied. The key benefits are that the UPS is compatible with the upstream source, the mains or any kind of generator and the transfer of power between source and load is more efficient. This results in a saving in terms of scale of sources, cables and protective devices.

KEY FEATURES

FEATURES

- User-friendly interface

- Monitoring, managing and shutdown software

- Removable blowers

- Front access

COMMUNICATION

- RS232 serial port

- USB port

- Remote EPO

- External manual bypass status

- Battery Switch status

- Diesel Mode

OPTIONAL

- Web / SNMP

- Modbus

- Relays

- Modem

- Remote panel

OPTIONS

- Parallel capacity / redundancy

- Sync control for dual feed systems

- Isolation transformer

- External bypass

- External battery cabinets

- Battery switch box

- Battery thermal probe

- Transformers / autotransformers for voltage adaption

- Top cable entry

DESCRIPTION

Reduced overall costs of ownership

The UPS AEG HPI has a new Wise ECO function which enables a total operating efficiency of between 95 % and 98 %. This mode, referred to as “Intelligent ECO mode”, significantly reduces the utility costs associated with operating a device of this type. Moreover, this increase in efficiency results in the production of less waste heat, minimizing cooling / air-conditioning costs. This represents a double saving to the energy conscious user. The Wise ECO mode function uses continual monitoring techniques to review the input characteristics of the supply. This means that if the supply line drops or fluctuates outside of acceptable conditions, the UPS uses the internal inverter to support the load. This is achieved through a fast, fully static transition from VFD to VFI mode.

Triple Intelligence

If the application requires extremely flexible and reliable UPS protection, the UPS AEG HPI is ideal. It delivers advanced features based on state-of-the-art total digital control. This control incorporates dual DSP (Digital Signal Processing) and μC (Micro controller) technologies. The system design ensures that auxiliary power supplies and processors are no longer single points of failure which could compromise the availability of clean power to the load. The HPI is designed to overcome the limitations imposed by other older, designs. With its distributed control architecture, HPI will always have a UPS circuit protecting the load; furthermore, the status of most critical components is constantly monitored, allowing predictive maintenance and avoiding unexpected breakdowns. UPS AEG HPI’s working state can be easily monitored by any Building Management System and via LAN / WAN.

Parallel systems with “hot swap” modularity

The AEG HPI UPS solution offers parallel options in both redundancy and capacity modes, providing the possibility for both extra system resilience and increased capacity. The parallel control circuitry associated with these units is fully digital and acts on both active and reactive power on each of the three output phases. This allows accurate load current sharing among the UPS units even during transient conditions. Parallel control is distributed between all units and communication is achieved through the use of a CAN bus connection loop. This has the effect of producing a highly reliable system with “no single points of failure”. Intelligent design of the system connections allows for easy installation and easy future upgrades, this allows for upgrading the field without difficulty. In the modular arrangement, units can be added or removed “hot” without load disturbances or the need to switch to bypass. Smart Parallel functions facilitate the automatic switching off of units where the total power requirements of the load is provided by fewer than the total number of UPS units attached. This is commonly known as “load based shutdown” and maximizes the efficiency of the complete system by keeping the load on each module at an optimum level. Two independent paralleled systems can be synchronized (Sync Control) in order to feed downstream STS’ for seamless transfers.

Protection for every application

VFI double conversion topology in this equipment offers built-in inverter galvanic protection, completely isolating the output power from all input power anomalies, delivering fully conditioned pure sine-wave output. In VFI mode (Online) the unit delivers an excellent 95 % efficiency. Because of the technology and topology used, no additional losses are generated to achieve low input harmonics or input / output galvanic isolation. The UPS AEG HPI unit is designed to provide excellent output voltages suited to very demanding applications with either 100 % step load, unbalanced, non-linear or modern IT loads. It also provides exceptional performance: with a power factor of up to 0.9 (lagging or leading), there is no requirement to de-rate the unit.

Accurate Battery Management

Batteries are electro-chemical devices, which store charge chemically; as such their performance degrades with time. The UPS AEG HPI performs ABM (Advanced Battery Management) according to battery manufacturers’ requirements. Following a UI characteristic curve, the charger charges at a constant current appropriate for the battery type used, preventing detrimental excess charging. In addition to the float voltage level, boost charge can be set, optimizing the recharge time when there is the possibility of consecutive power outages within a short period. ABM also reduces the residual ripple current (one of the causes of premature battery wear), as well as protecting the battery from damaging deep discharges. Automatic battery temperature compensation charge voltage may be implemented, charging the battery more appropriately and increasing battery life. By means of the DCM (Dynamic Charging Mode), very long battery autonomies can be achieved without increasing total charge time. This is achieved through the implementation of an intelligent increase in maximum battery charge current when the maximum inverter power is not being drawn by the load. An integrated periodical battery testing function tests and monitors battery health, providing advanced warning to guide the application of preventive maintenance.

Easy installation, operation and maintenance

The AEG HPI can be installed up close to walls or other cabinets as cooling air is expelled through vents on the top of the unit. This new design gives the user a significant saving in floor utilization. This makes the HPI an ideal solution where space is at a premium. Despite this modern compact design, all critical components are accessible from the front of the unit; this improves accessibility to allow regular maintenance and reducing Mean Time to Repair (MTTR).